From Tracks to Rollers: Exploring High-Quality Undercarriage Parts for each Requirement

Wiki Article

Make The Most Of Efficiency With Long Lasting Undercarriage Components

In the realm of hefty equipment and tools, the duty of undercarriage components is vital in guaranteeing optimum performance and durability. The efficiency and performance of these components can substantially affect the overall operation of equipment, making the selection of sturdy undercarriage components a crucial decision for operators and supervisors alike. By exploring the complex connection between toughness and performance in undercarriage parts, a much deeper understanding of the subject emerges, clarifying the critical elements that drive operational success. As we navigate via the complexities of undercarriage component, maintenance, and long life selection, an extensive expedition waits for to reveal the vital techniques for accomplishing peak efficiency in heavy-duty applications.Benefits of Making Use Of Sturdy Undercarriage Components

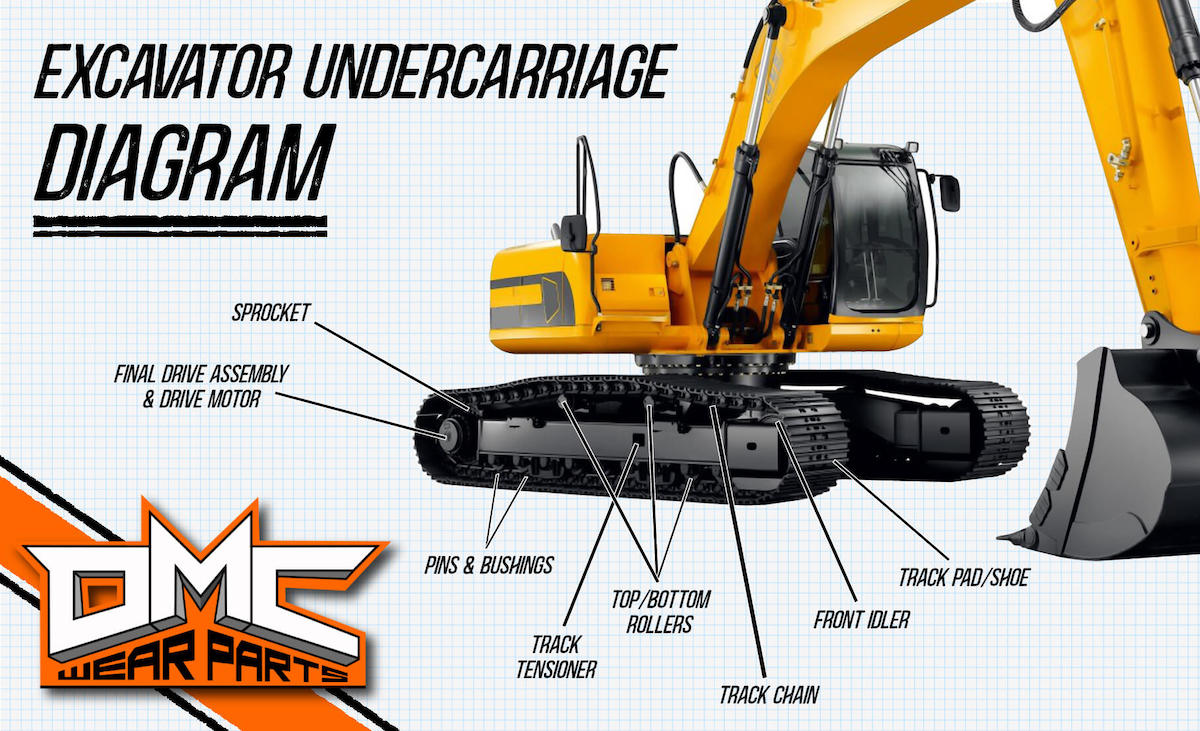

Utilizing durable undercarriage components not only enhances the durability of heavy equipment however also minimizes maintenance expenses significantly. By purchasing top quality undercarriage components, such as tracks, rollers, idlers, and gears, tools operators can experience boosted uptime and improved total efficiency.

Additionally, the durability of hefty equipment is straight connected to the quality of its undercarriage parts. Resilient elements can stand up to the roughness of demanding applications, guaranteeing that the equipment continues to be functional for prolonged durations. Therefore, operators can avoid costly downtime and maintenance expenditures, inevitably making the most of the return on financial investment for their machinery.

Aspects Affecting Undercarriage Durability

The resilience of undercarriage components in heavy equipment is affected by various important factors that straight influence efficiency and durability. High-quality materials, such as hardened steel, are crucial for enduring the severe conditions and hefty tons that undercarriage parts are subjected to - undercarriage parts.Moreover, environmental variables can have a considerable effect on the durability of undercarriage parts. Exposure to rough materials, severe temperatures, and extreme working problems can increase wear and tear on undercarriage parts. Selecting undercarriage components that are particularly designed to stand up to these ecological obstacles is essential for ensuring resilience.

Additionally, the layout and design of undercarriage components have a straight influence on their toughness. Components that are designed to distribute tons evenly, lower rubbing, and minimize stress focus are more most likely to have a longer lifespan - undercarriage parts. By thinking about these crucial factors, equipment drivers can make the most of the resilience and performance of their undercarriage components

Maintenance Tips for Prolonging Undercarriage Life

Implementing regular upkeep regimens is essential Check Out Your URL for prolonging the life-span of undercarriage parts in heavy equipment. Additionally, make sure that the undercarriage is properly oiled according to maker standards to decrease friction and stop premature wear.Another important upkeep pointer is to maintain the undercarriage clean from dust, rocks, and particles. Buildup in the undercarriage can increase wear and deterioration, resulting in pricey fixings. Cleaning the undercarriage after procedure in extreme conditions is advised to avoid these problems.

Lastly, tracking and recording upkeep tasks can assist in producing a positive maintenance timetable. Maintaining in-depth documents of repair work, examinations, and replacements can provide beneficial understandings into the undercarriage's condition and performance gradually, assisting in anticipating and protecting against possible failings. By adhering to these upkeep suggestions faithfully, drivers can dramatically boost the sturdiness and performance of undercarriage parts in hefty machinery.

Choosing the Right Undercarriage Elements

Picking appropriate undercarriage components is crucial for making best use of the performance and durability of heavy equipment. There are numerous elements to think about when it comes to selecting the ideal undercarriage components. One essential aspect is understanding the details needs of the maker and the setting in which it will certainly run. Different applications may call for different types of undercarriage components, such as tracks, sprockets, idlers, and rollers. It is vital to choose components that are created to endure the certain conditions the equipment will come across, whether it be harsh surface, abrasive products, or extreme temperature levels.Opting for trustworthy brand names understood for creating high-performance and sturdy undercarriage components can considerably influence the general efficiency and long life of the machinery. By carefully choosing the best undercarriage components, devices owners can boost efficiency, minimize downtime, and expand the lifespan of their hefty machinery.

Study: Enhanced Performance With Long Lasting Parts

Incorporating long lasting undercarriage components has demonstrated substantial enhancements in machinery efficiency. One study entailed a construction company that upgraded its excavator's undercarriage components to extra long lasting options. The firm observed a remarkable decrease in downtime as a result of undercarriage maintenance, causing boosted productivity and expense savings. The sturdy useful link components stood up to severe working conditions, reducing damage significantly.In an additional instance, a mining procedure replaced the undercarriage parts of its excavator with premium, sturdy options. This switch brought about a remarkable renovation in the excavator's maneuverability and overall performance. The device could navigate challenging terrains more successfully, leading to boosted operational performance and decreased fuel intake.

In addition, a logging company purchased sturdy undercarriage components for its forestry equipment. The upgraded components showed extended life expectancy and boosted resistance to abrasion from harsh surface. As a result, the company experienced decreased maintenance prices and better tools uptime, inevitably boosting its lower line. These study emphasize the concrete benefits of using durable undercarriage parts in optimizing equipment performance and durability.

Verdict

In final thought, utilizing sturdy undercarriage parts can dramatically enhance efficiency and durability of heavy machinery. Case researches have revealed that investing in durable undercarriage components can lead to boosted general performance and performance in different industries.The performance and performance of these components can substantially influence the total procedure of machinery, making the selection of sturdy undercarriage parts a crucial choice for operators and supervisors alike.Including sturdy undercarriage components has shown considerable enhancements in machinery efficiency. These instance studies emphasize the substantial advantages of making use of durable undercarriage components in enhancing machinery efficiency and longevity.

In verdict, using durable undercarriage components can substantially enhance efficiency and longevity of heavy machinery (undercarriage parts). Instance studies have actually shown that investing in durable undercarriage components can see here lead to enhanced overall efficiency and productivity in numerous industries

Report this wiki page